Jan 28, 2022 · 1. Take 1 wheel off the trailer to access the hub assembly. Loosen the nuts on all wheels with a lug wrench while the trailer is on the ground. Jack the trailer up just enough to lift the wheels off the ground. Finish unscrewing the nuts on 1 wheel with the lug wrench, remove them, and slide the wheel off the hub. Learn more here: AU http://bit.ly/2z7sRwk NZ http://bit.ly/2izKduWThis video is a quick guide to replacing the bearings only without the races, to replace th...

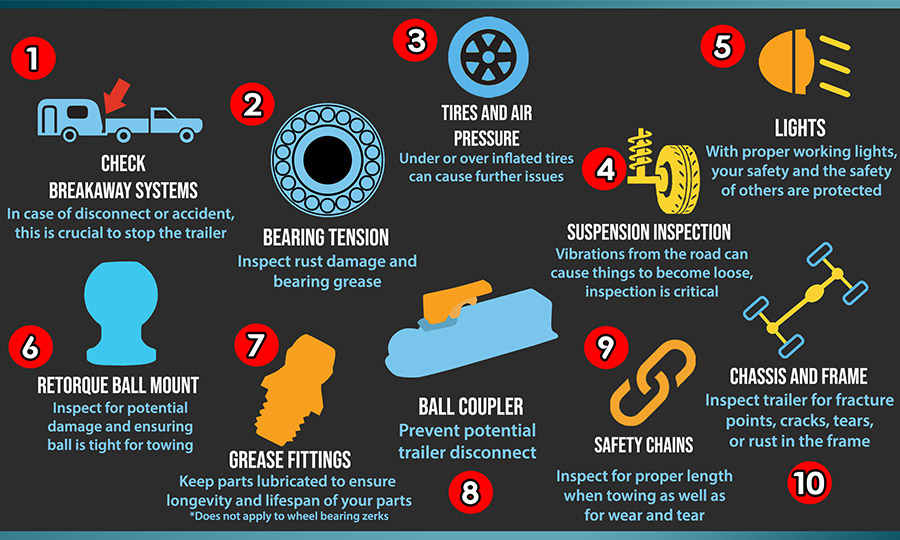

Nov 24, 2010 · Trailer wheel bearings can become damaged or worn out over time just like any other, so it is important that you remember to maintain them. Wear and tear through regular use is a gradual process, but you can cause unnecessary damage through two easily avoidable mistakes.

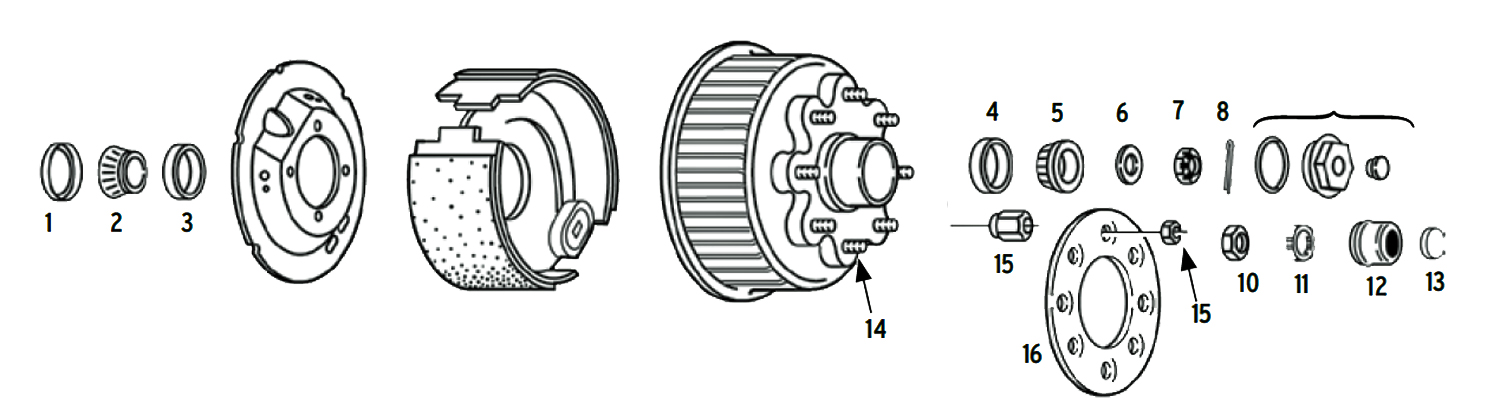

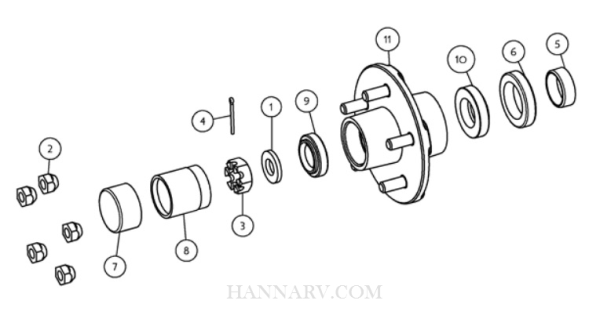

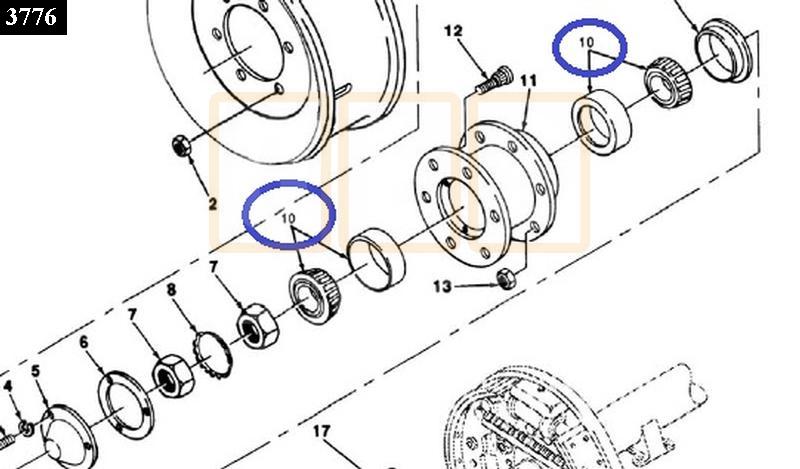

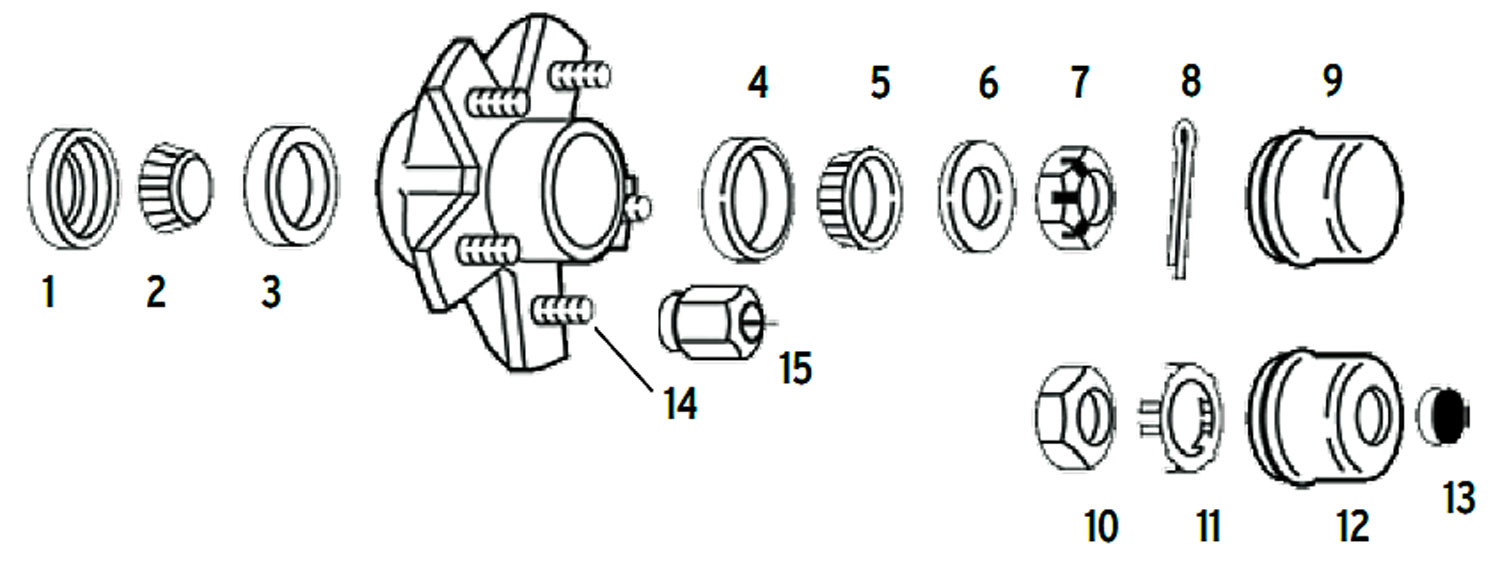

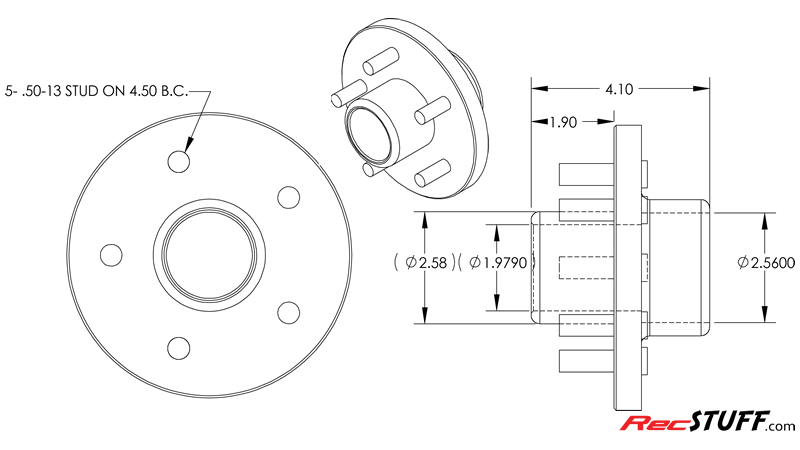

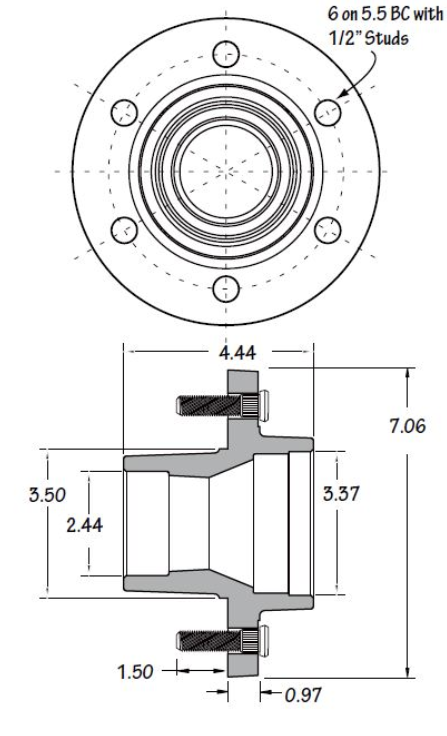

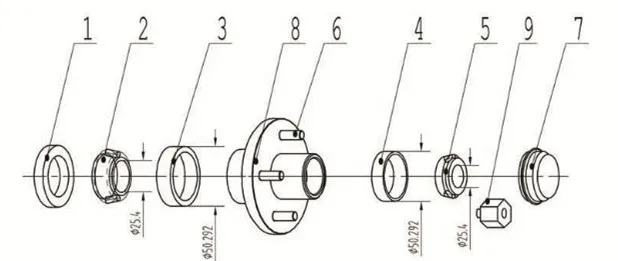

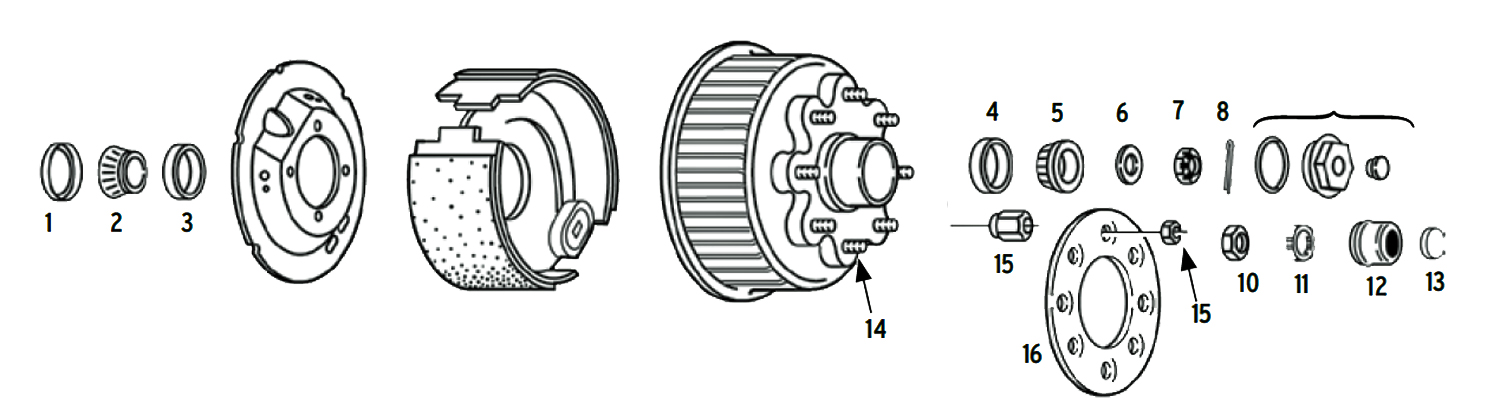

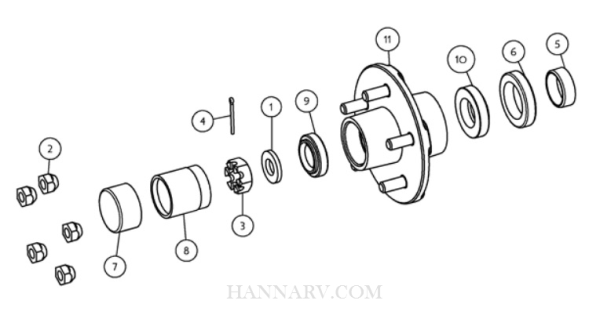

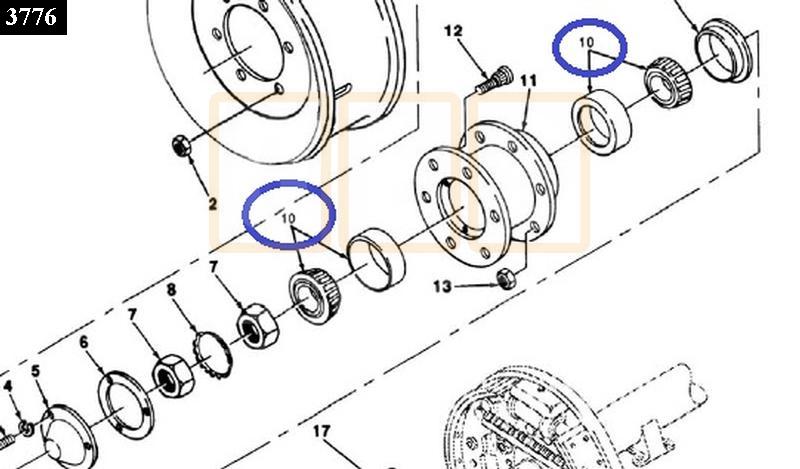

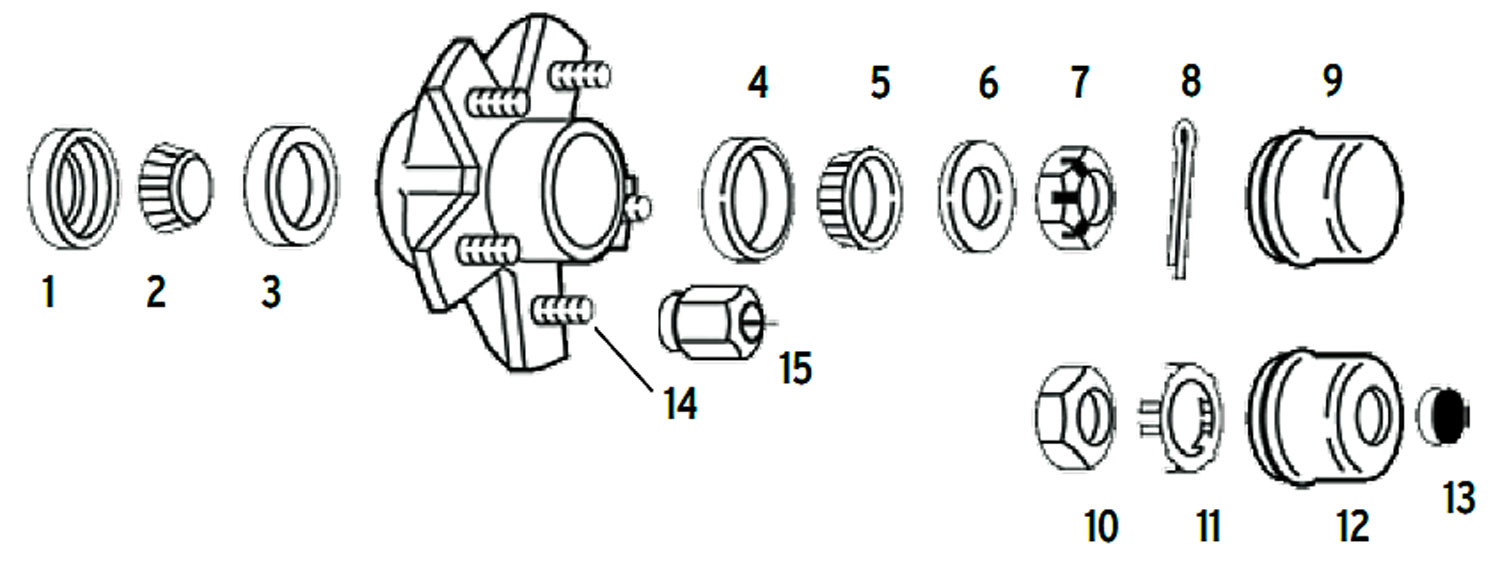

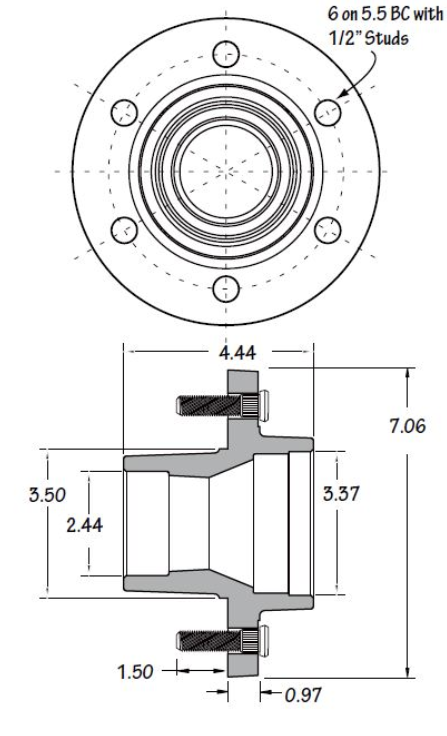

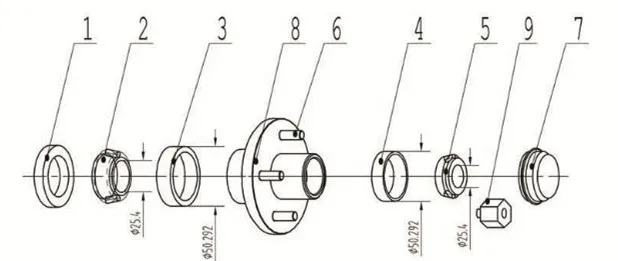

Trailer wheel bearing diagram

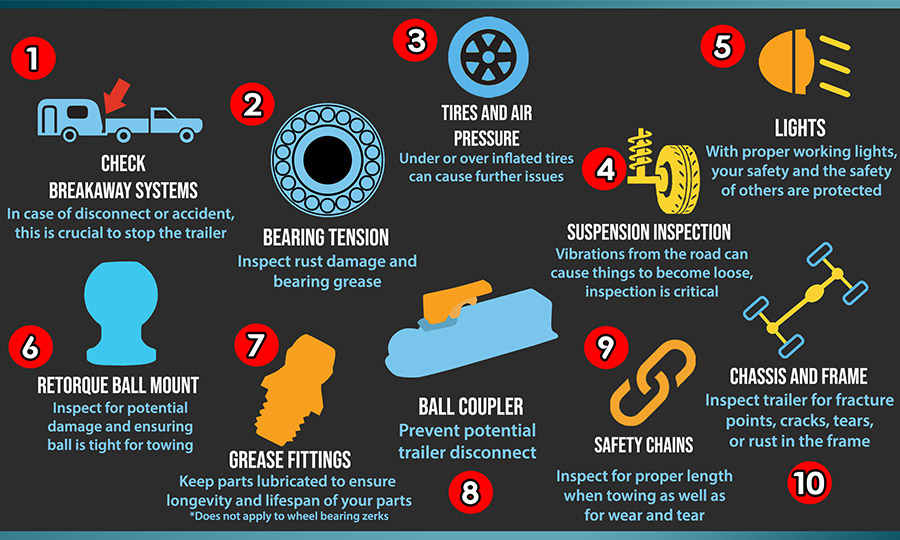

Pre-Adjusted Wheel Bearing Adjustment Procedures The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to .127 mm). This procedure applies to steer, drive and trailer axle assemblies using conventional double nut or single nut systems on Class 6, 7 and 8 trucks.

Trailer wheel bearing diagram. Pre-Adjusted Wheel Bearing Adjustment Procedures The goal of this recommended procedure is to achieve a verifiable wheel bearing end play of 0.001” to 0.005” (.025 mm to .127 mm). This procedure applies to steer, drive and trailer axle assemblies using conventional double nut or single nut systems on Class 6, 7 and 8 trucks.

Hubs & Bearings | BoatUS

Trailer Hub-Drum 8 Bolt On 6 1/2" Bolt Circle For 8k Axles ...

Shorelander SS734 1-3/8 Inch x 1-1/16 Inch Hub And Bearing ...

Trailer Wheel Bearing Kit for M103, M105 and M107 - Oshkosh ...

What type of hub is this? | Retro trailers, Vintage camper ...

SKF Bearings and Seals

Electric Trailer Brake Replacement Tutorial

Repacking Trailer Wheel Bearings (DIY) | Family Handyman

Trailer Hub repair

Triton Trailer Bearing Maintainence ? - Page 2

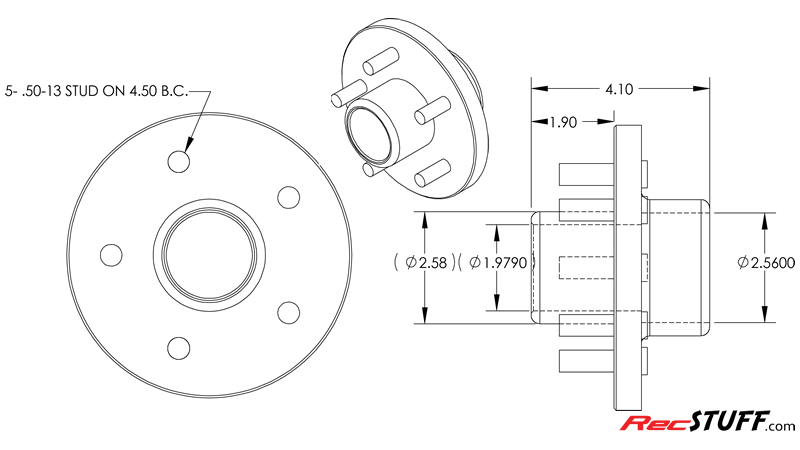

Trailer Idler Hubs 5 Bolt On 4 1/2", 4 3/4", 5" and 5 1/2 ...

Trailer Parts Superstore - Hub Technical Information

How to Determine Replacement Trailer Wheel Bearing Sizes ...

Trailer Parts Superstore - Hub Technical Information

Trailer Parts Superstore - Hub Technical Information

TRAILER WHEEL BEARING KITS

How Genuine BB® Works | BearingBuddy

Galvanized Boat Trailer Wheel Hub For Sale | Custom Made

Cleaning your Trailer's Wheel Bearings | Prescott Trailers

Semi Trailer Wheel Hub Assembly 5 Bolts Wheel Hub Sale For ...

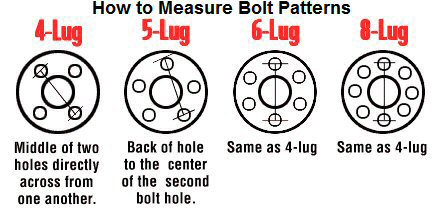

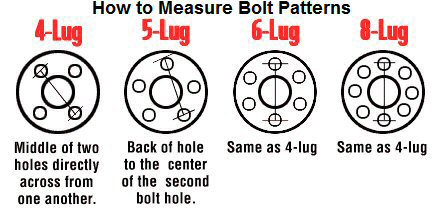

How to Measure your Trailer's Wheel Bolt Circle Lug or Bolt ...

Boat Trailer Wheel Bearing Maintenance | Boating Mag

5 Bolt, High Speed, Pre-Greased Trailer Hub - 1350 Lbs. Capacity

How to Replace Bearings on a Trailer (with Pictures) - wikiHow

Wheel Bearing & Seal Service

Trailer Hub Assembly 8 Bolts Wheel Hubs for Trailers - China ...

DIY Safe and Trouble-Free Boat Trailering | West Marine

5 Bolt High Speed Empty Trailer Hub With Races Only

Torklift Central | Trailer Wheel Bearing Services | Seattle ...

wheel bearing inner trailer M1101 M1102, 45,00 €

Built Dexter Tough.

Trailer Terminology | Dennis Allen's "Boating Basics"

Replacing and Rebuilding Ranger Cool Hub Seals - Walleye ...

Hub 6 bolt 3000# E-coat Kit

SKF Bearings and Seals

Trailer greasing question - The Hull Truth - Boating and ...

ATVstore.com :: Trailer Bearings | Harbor freight folding ...

Boat Trailer Hub Painted Steel 5 on 4 3/4 Spacing fits 3500 lb. Axles

Wheel Bearing and Hub Assembly

Wheel Bearing Hub 4 Studs Trailer Axle Wheel Hub - Buy ...

4x4'' PCD trailer hub assembly

0 Response to "41 trailer wheel bearing diagram"

Post a Comment