44 national cranberry cooperative process flow diagram

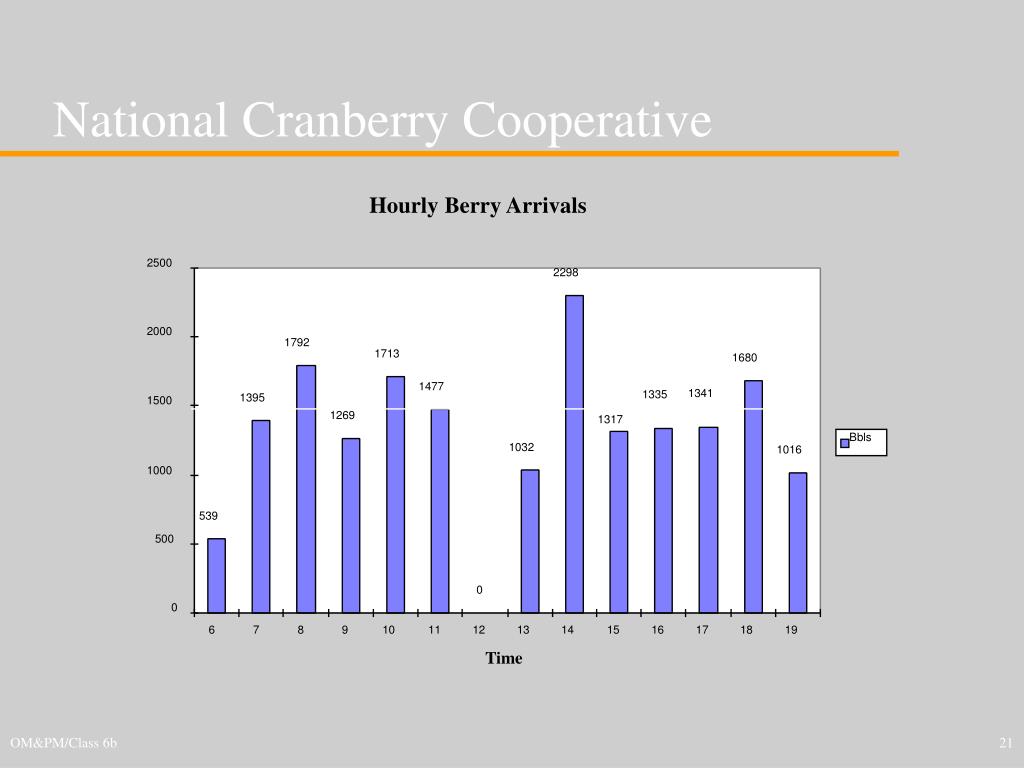

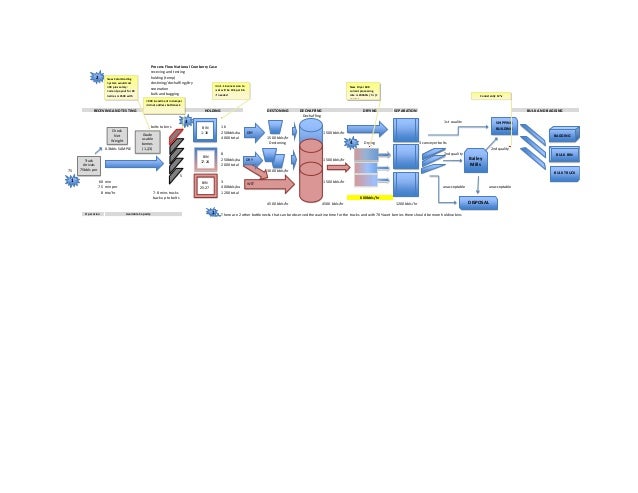

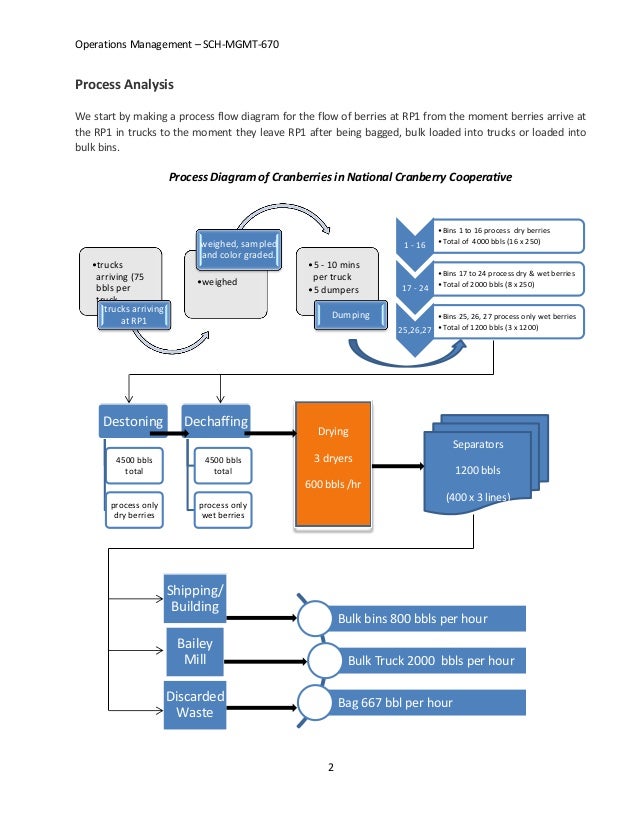

National Cranberry Process Flow Diagram Unload weighed/ graded tested/ sampled destone dechaff dry separate Bag 667 bbl/hr dry 1-16 250 bbls =4000 bbls both 17-24 250 bbls =2000 bbls wet 25-27 3x400 bbls = 1200 bbls 2 x 1500 bbls/hr 1500 bbls/hr 5-10 min/truck 3 x 200 bbls/hr 3 x 400 bbls/hr destone 2 x 1500 bbls/hr dechaff 1500 bbls/hr Bulk Truck 2000 bbl/hr Bulk Bins 800 bbl/hr Freeze Freeze ... Below is an excerpt from the National Cranberry Cooperative Case. Questions are below: 1. Draw a process flow diagram showing the major process steps, inventories, and flows.Indicate the capacity at each of the process steps. You should assume: a. 16,000 barrels per day is the average of deliveries over the 20 days from 9/20--‐10/9 b.

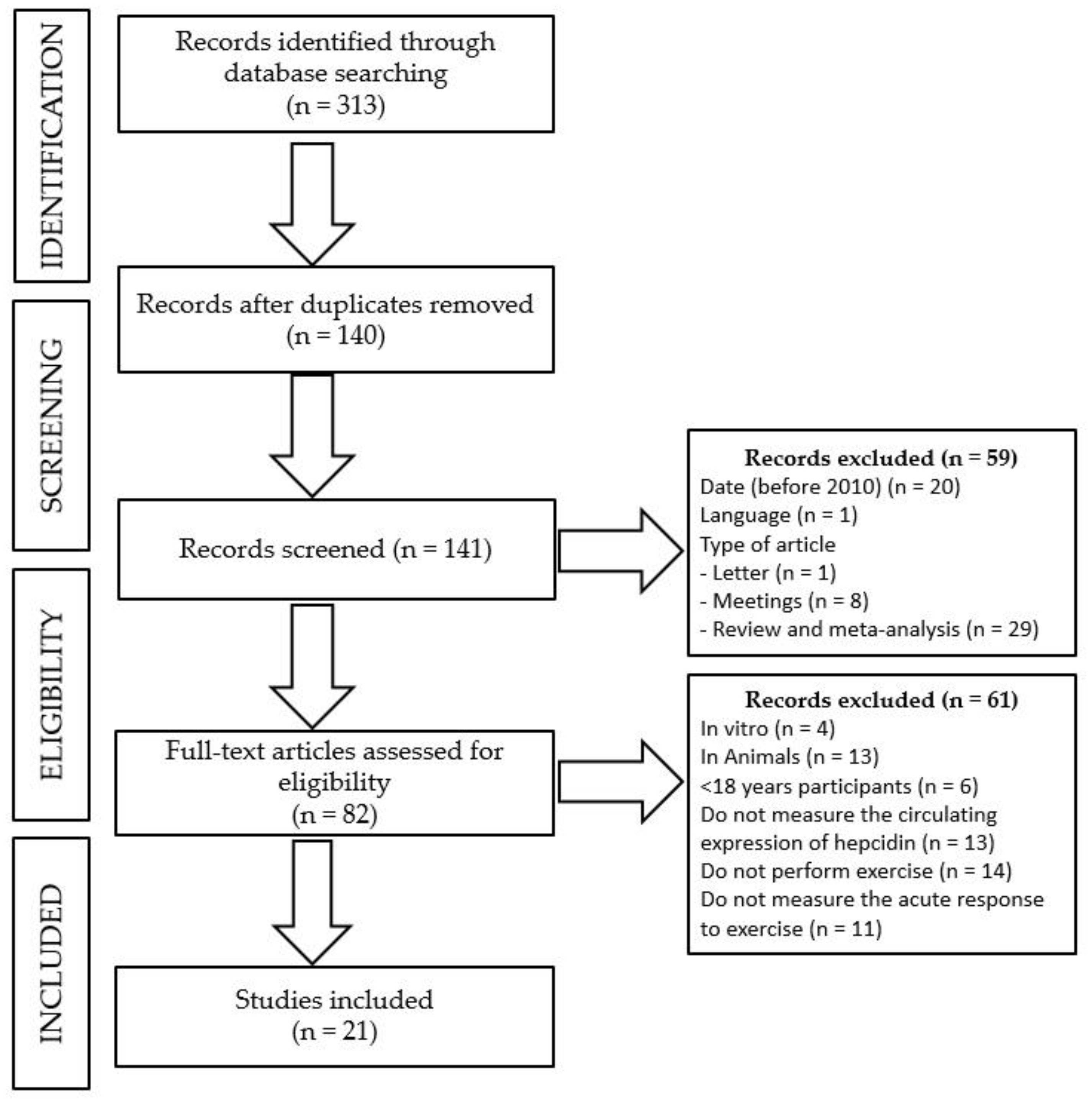

National Cranberry Cooperative 1798 Words | 8 Pages. Table of Contents 1.) Introduction 2 2.) Process Analysis 2 3.) Process Flow at National Cranberry Cooperative 4 4.) Installing a Light Grading System 5 5.) Decreasing the truck waiting time 6 6.) Bag pack or Bulk Pack 8 7.) Conclusions 9 1.)

National cranberry cooperative process flow diagram

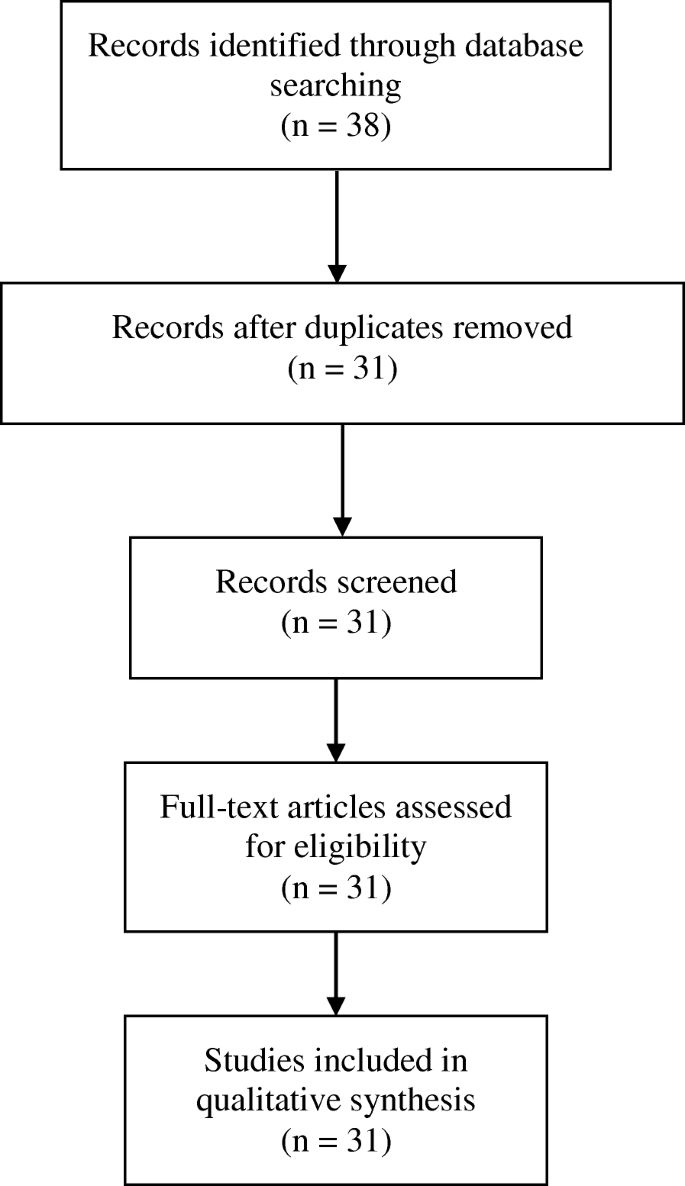

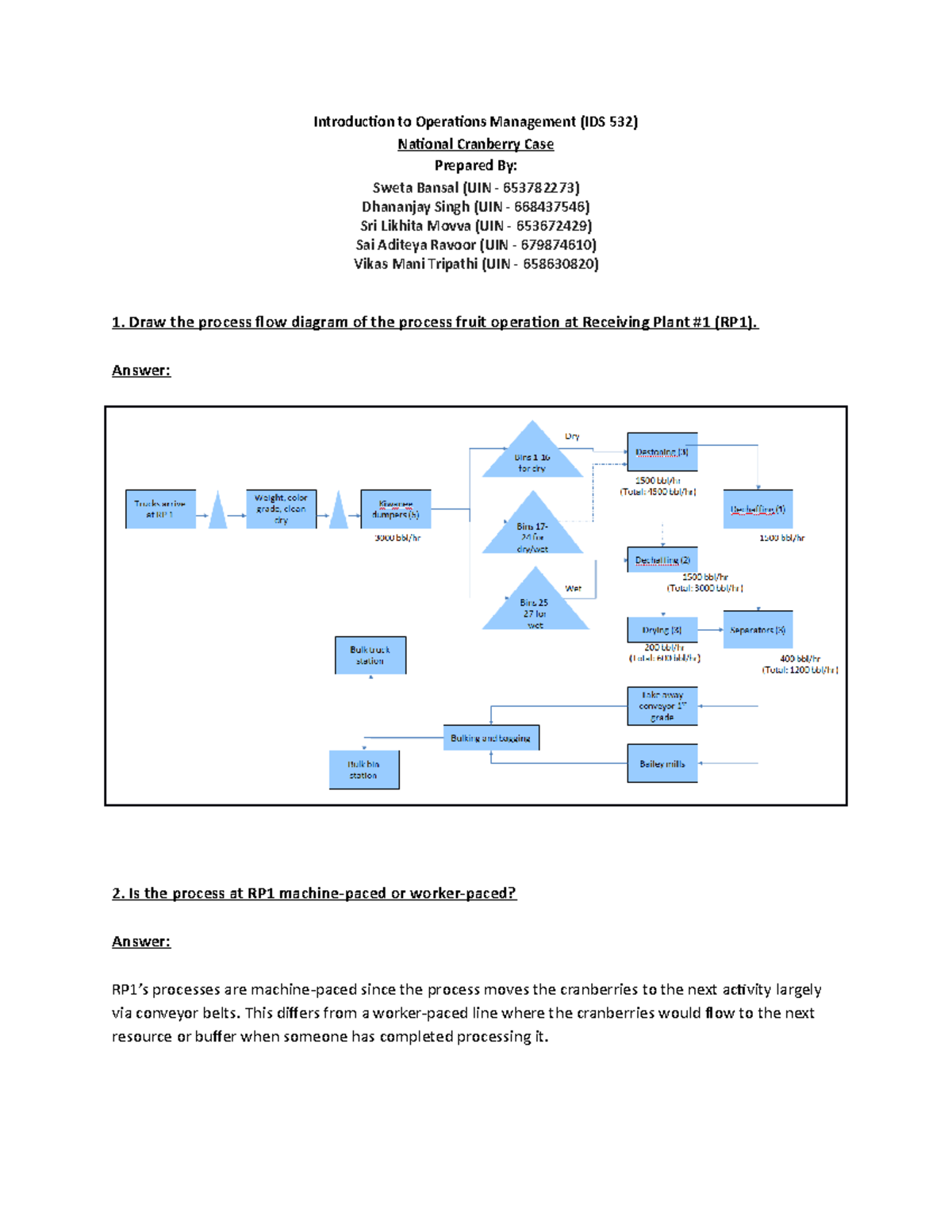

Process Flow Diagram 2 National Cranberry Cooperative A business case report by A.Chhatre, J. Parkinson, A. Sivaraman, M. Thiruvarasu The process flow diagram of the process fruit operation at NCC is as shown on the next page. 3 National Cranberry Cooperative A business case report by A.Chhatre, J. Parkinson, A. Sivaraman, M. Thiruvarasu 4 ... National Cranberry Cooperative study guide by Kyong_do includes 12 questions covering vocabulary, terms and more. Quizlet flashcards, activities and games help you improve your grades. Search. Create. ... Diagram the process flow for process fruit at RP1. Note the capacities at the processing stages and the storage capacities of the storage bins. National Cranberry Cooperative 1996 Case Solution,National Cranberry Cooperative 1996 Case Analysis, National Cranberry Cooperative 1996 Case Study Solution, Process flow diagram: Please refer to excel spreadsheet for the process flow diagram Capacity at each step in bbls: INPUTS Operation Available Capacity

National cranberry cooperative process flow diagram. National Cranberry Cooperative. Background National Cranberry Cooperative (NCC) had faced operational problems at Receiving Plant #1 (RP1) during the peak harvest season in the fall of 1995‚ which had resulted in unhappiness of the owners of the Co-operatives and high labour cost‚ despite the purchase of an additional dumper. To avoid the same problems in the coming peak season‚ it is ... THE COMPANY The Receiving Plant I (RPI) of National Cranberry Cooperative (NCC) processes both wet and dry cranberries in a highly mechanized process involving 400 workers during peak season. ... PROCESS FLOW. The process flow diagram is attached as Exhibit A ANALYSIS From Figure E in the case Delivery begins at 7 AM Processing begins at 11 AM ... Wet berry only bins 25-27, capacity 1 200 (400 bbl/bin) Wet or dry berry bins 17-24, capacity 2 000 (250 bbl/bin) Wet berry bins will be full after 5.25 hours. 3200/609=5.25 (12:15 PM) Short term: 1. Start process earlier (dechaffing at 7AM, not 11AM) 2. Schedule truck arrival time --> four-hour shifts. Process Diagram of Cranberries in National Cranberry Cooperative •trucks arriving (75 bbls per truck trucks arriving at RP1 •weighed weighed, sampled and color graded. •5 - 10 mins per truck •5 dumpers Dumping 1 - 16 •Bins 1 to 16 process dry berries •Total of 4000 bbls (16 x 250) 17 - 24 •Bins 17 to 24 process dry & wet berries ...

National Cranberry Cooperative Background Process Flow Case Assumptions Agenda National Cranberry Cooperative Implementation of 2 new dryers and temporary storage space to reduce truck wait time to 0-20 minutes Turn RP1 into a revenue maker in the off-harvest season Decrease the national cranberry cooperative case solution This is a clear indication of the imperfect quality checking system that results in wastage of valuable money and time as well. In addition to that, this grading criteria have created differences and clashes between the cultivators and the marketers. Process Diagram of Cranberries in National Cranberry Cooperative •Bins 1 to 16 process dry berries weighed, sampled 1 - 16 •Total of 4000 bbls (16 x 250) and color graded. •trucks •5 - 10 mins arriving (75 per truck •Bins 17 to 24 process dry & wet berries •weighed •Total of 2000 bbls (8 x 250) bbls per •5 dumpers 17 - 24 truck trucks arriving Dumping •Bins 25, 26, 27 process ... 1 Answer to National Cranberry Cooperative Case Analysis 1.Draw the Process Flow Diagram showing the major process steps, inventories and flows. Indicate the capacity at each of the process steps. (You may ignore the "waste" figures in examining the capacity of the operations.) 2.16,400 barrels per...

NATIONAL CRANBERRY CO-OPERATIVE CASE STUDY. Nishi Sharma In 1971, National Cranberry Cooperative faced recurring operational problems that affected the productivity and relationship of NCC to growers. This analysis will discuss how NCC can improve its operation before the peak-season comes in. The analysis was based from facts cited in the case ... View Homework Help - National Cranberry Case.docx from OPERATIONS 101 at New York University. a) Draw a process flow diagram for the process fruit operation of RP #1. Assume the arrival Trucks Mark the capacity and utilization of each resource in the process flow diagram at the end of this document. Briefly describe how you calculate the capacity and utilization here. [20 points] On average, 18000 barrels arrive over the 12hr p that the business is open. This means approximately 1500 barrels of berries are input into the process per hour (18000barrels/12hrs). The capacity of the ... THE COMPANY The Receiving Plant I (RPI) of National Cranberry Cooperative (NCC) processes both wet and dry cranberries in a highly mechanized process involving 400 workers during peak season. ... PROCESS FLOW. The process flow diagram is attached as Exhibit A ANALYSIS From Figure E in the case Delivery begins at 7 AM Processing begins at 11 AM ...

Mark the force and engagement of each resource in the process flow diagram at the end of this document. short suck up how you calculate the substance and exercise here. 20 points On average, 18000 barrels go far over the 12hr span that the business is open. ... . 20National Cranberry CooperativeCase Report National Cranberry Cooperative Fill in ...

As per the above process flow diagram and the capacity of each process, drying process appears to be the bottleneck process as it has minimum capacity. ... Mount Everest-1996 Mount Everest—1996 Mount Everest-1996 1996 Welfare Reform in the United States National Cranberry Cooperative National Cranberry Cooperative Case: National Cranberry ...

national cranberry cooperative process flow diagram Urban development over the Edwards aquifer in the Austin, Texas, area has caused concerns about the availability and quality of water in the aquifer.

Om Group 1 Pdf Introduction To Operations Management Ids 532 National Cranberry Case 1 Draw The Process Flow Diagram Of The Process Fruit Operation At Course Hero

View Notes - Case#1_MGT504.docx from MGT 504 at DePaul University. 1. National Cranberry Cooperative: Process Flow Diagram Trucks (avg 75 bbls) Weigh, ...

Effects Of Cranberry Consumption On Features Of The Metabolic Syndrome A Systematic Review And Meta Analysis Of Randomized Control Trials Emerald Insight

National Cranberry Assignment. Case Study: "National Cranberry Cooperative" Question 1: "Draw a Process Flow Diagram of Receiving Plant 1". For each step in the process indicate the resource pool, number of resources in the pool, total capacity of the pool. There are actually 27 holding bins, some of which can hold either dry or wet ...

Treatment And Prevention Of Recurrent Lower Urinary Tract Infections In Women A Rapid Review With Practice Recommendations Journal Of Urology

Page 1of 9 NCC Case Study Analysis NCC Process Flow Diagram Trucks arriving at RP1 Dumping - Average dumping time is Trucks arriving at The berries 7.5 minute per truck. RP1. The average weighed, weight of barriers - No. of Dumper are 5 sampled and on truck is 75 bbls color graded - The total capacity of per truck dumpers = 5x75x60/7.5=3000 bbls/hr Temporary Holding - Bins 1 to 16 process are ...

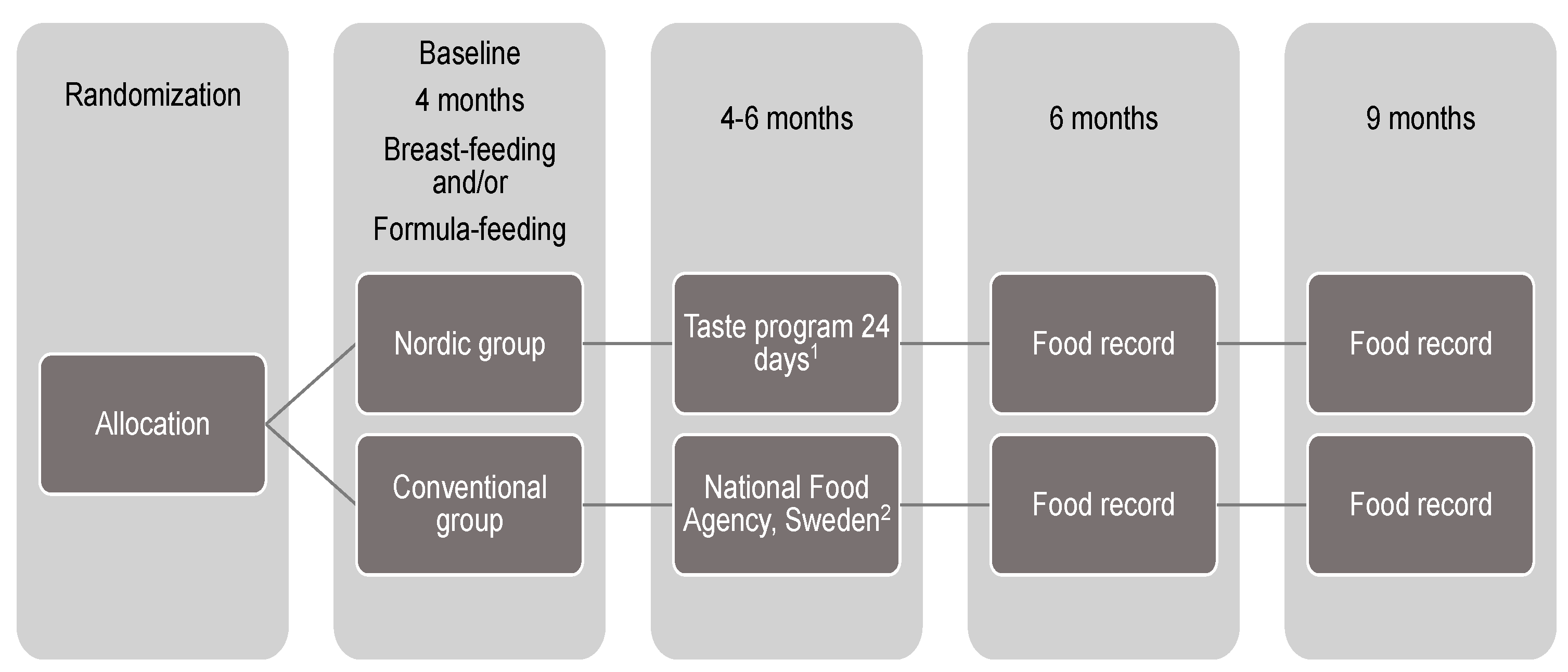

Nutrients Free Full Text Protein Reduced Complementary Foods Based On Nordic Ingredients Combined With Systematic Introduction Of Taste Portions Increase Intake Of Fruits And Vegetables In 9 Month Old Infants A Randomised

National Cranberry Cooperative Process FLow Diagram. Prakash Nayak. Loading Preview. Sorry, preview is currently unavailable. You can download the paper by ...

National Cranberry Cooperative: Process Flow Diagram Dry berries 30%= 475 b/hr 30%= 250 b/hr Wet berries 70%=1108 b/hr 70%=583 b/hr Weigh, Test Berries Truck Queue Kiwanee Dumpers 5 @ 600 b/hr each =3000 b/hr Dry Storage Wet Storage 1-16: 4000 b add 17-24: 6000 b 25-27: 1200 b add 17-24: 3200 b Destone [email protected] b/hr

National Cranberry Cooperative (Abridged) Here's the problem‚ gang… We now that the bottleneck in the process is the Drying unit. Using the diagram‚ we can assess: 1.TPT is 19‚000*.7 wet barrels/12 work hrs in work day = 1108 wet bbls per day 2.

National cranberry case study. 1. National Cranberry Cooperative Process Flow: Receiving Cranberries Weighing Sampling Grading Dumping (If the dumping cannot be performed cranberries are held in the trucks until they can be processed) Storing Cranberries into Bins Dry bins Dual bins (you have to decide how these dual bins are allocated) Wet bins 1.

National Cranberry Cooperative Requires an analysis of both the process flows and the production control system used in a cranberry receiving plant. 1. What is your analysis of the process fruit operation at RP1? [Hint:] Draw a process flow diagram for RP1. State what assumptions you made in calculating the capacity of each station (bbl/hr).

Ppt 1 Operations Strategy 2 Process Analysis 3 Lean Operations 4 Supply Chain Management Powerpoint Presentation Id 6122181

National Cranberry Cooperative Analysis ...Case Analysis of National Cranberry Cooperative Team1. Report I. Summary <Process Flow Chart> <Operations> 1) Receiving and Testing ☞ RECEIVING * 243 trucks deliver 75 barrels(=7500 pounds) per truck on average * 75*243 = 18225 barrels (1822500 pounds) * Last truck arrived (1140min) - First truck arrived (411min) = 729min (=1140 - 411) → 729min ...

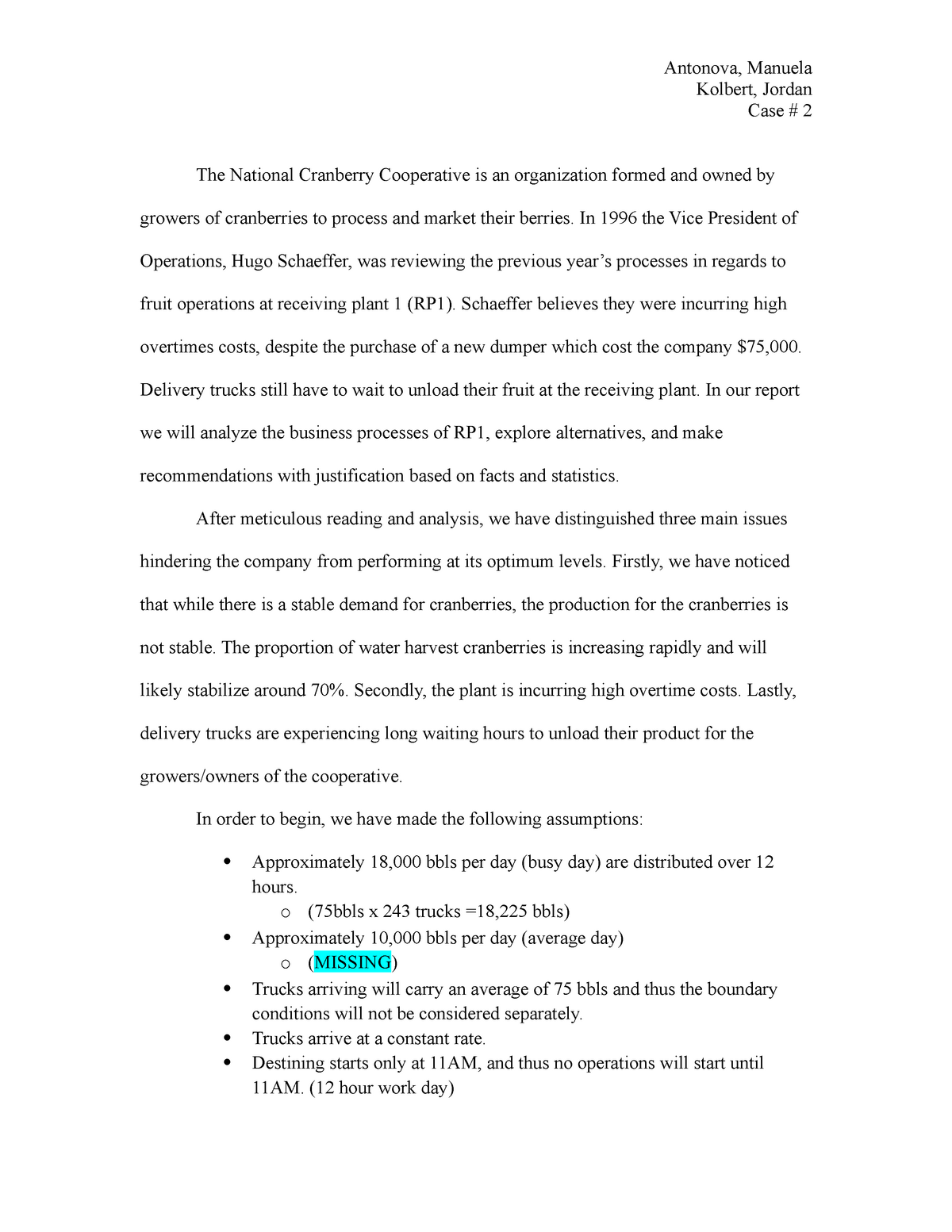

Process Flow at National Cranberry Cooperative 4 4.) Installing a Light Grading System 5 5.) Decreasing the truck waiting time 6 6.) Bag pack or Bulk Pack 8 7.) Conclusions 9 1.) Introduction This case analysis looks at the two primary problems at the receiving plant no. 1 (RP 1) faced by National Cranberry Cooperative during the cranberry harvesting period, viz. 1) too much waiting period for ...

Please find guidelines and ideas for National Cranberry Cooperative in the attached file. Running Head: NATIONAL CRANBERRY COOPERATIVE. National Cranberry Cooperative. Answer 1 Process Flow Diagram for wet and dry cranberries. Working Note: Arrival of berries- In the process fruit, first berries are arrived on receiving plant no.1.

National Cranberry Cooperative 1996 Case Solution,National Cranberry Cooperative 1996 Case Analysis, National Cranberry Cooperative 1996 Case Study Solution, Process flow diagram: Please refer to excel spreadsheet for the process flow diagram Capacity at each step in bbls: INPUTS Operation Available Capacity

National Cranberry Cooperative study guide by Kyong_do includes 12 questions covering vocabulary, terms and more. Quizlet flashcards, activities and games help you improve your grades. Search. Create. ... Diagram the process flow for process fruit at RP1. Note the capacities at the processing stages and the storage capacities of the storage bins.

Full Article Fruit Supplementation Reduces Indices Of Exercise Induced Muscle Damage A Systematic Review And Meta Analysis

Process Flow Diagram 2 National Cranberry Cooperative A business case report by A.Chhatre, J. Parkinson, A. Sivaraman, M. Thiruvarasu The process flow diagram of the process fruit operation at NCC is as shown on the next page. 3 National Cranberry Cooperative A business case report by A.Chhatre, J. Parkinson, A. Sivaraman, M. Thiruvarasu 4 ...

Oxidative Stress An Essential Factor In The Pathogenesis Of Gastrointestinal Mucosal Diseases Physiological Reviews

Effect Of Thermally Assisted Hydrodynamic Cavitation Hc Processing On Physical Nutritional Microbial Quality And Pectin Methyl Esterase Pme Inactivation Kinetics In Orange Juice At Different Time And Temperatures Arya

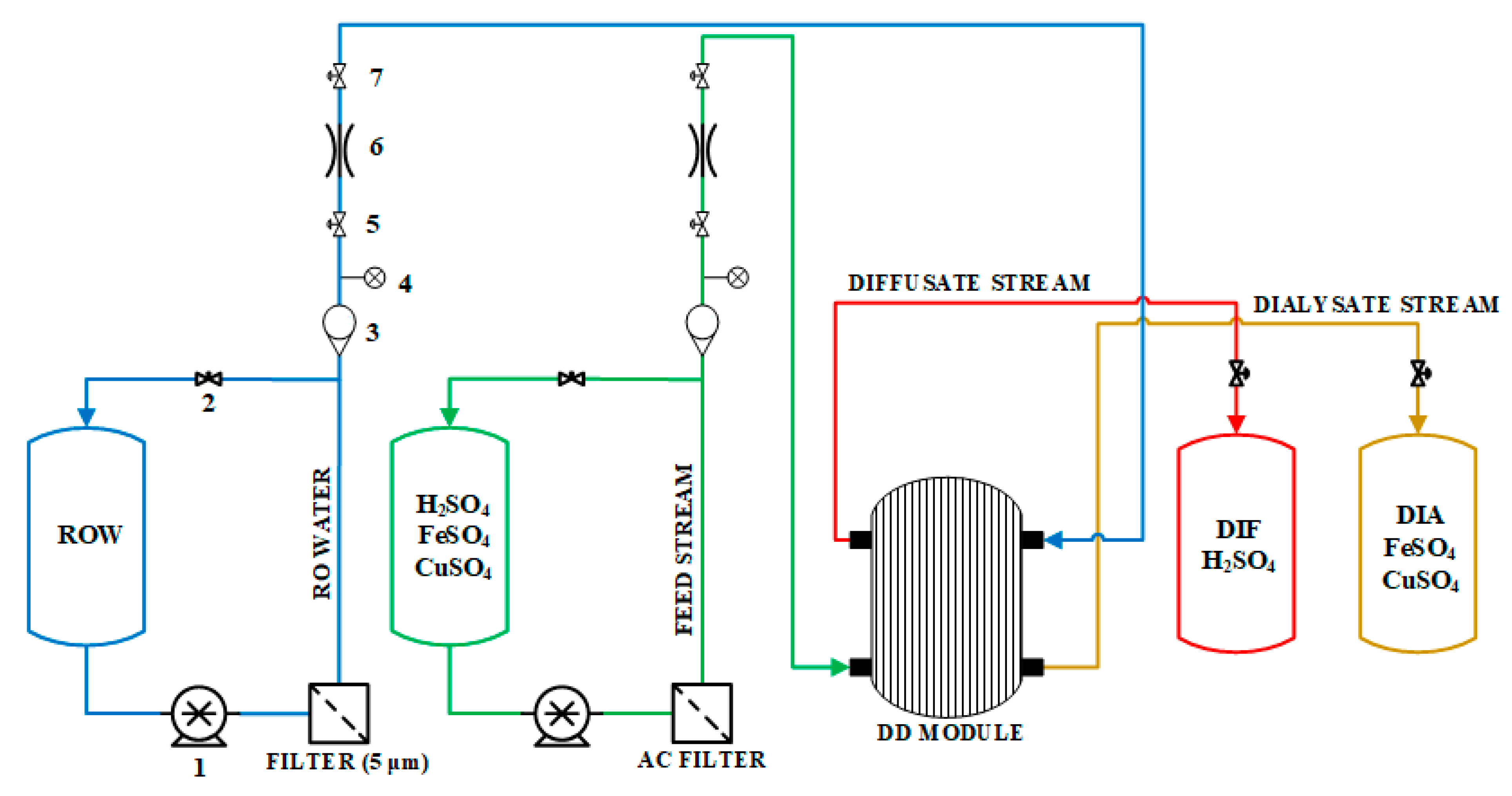

Ijms Free Full Text Recovery Of Spent Sulphuric Acid By Diffusion Dialysis Using A Spiral Wound Module Html

0 Response to "44 national cranberry cooperative process flow diagram"

Post a Comment